Safety Clothing Design

Once the order is confirmed, we move on to the technical department. Our in-house design team creates a prototype of the safety vest using specialized software and technical file including workmanship, quantity, colors, materials, packaging method, the important points, and all the details. The document is then sent to all the departments, purchasing, sales, production, Packaging, and QC, that is to make sure everyone is on the same page.

Material Sourcing

At the core of Lino Safety’s success is our careful selection of materials. We source top-quality fabrics, reflective tapes, and accessories that meet safety standards while maintaining competitive prices. This combination enables our clients to protect their brand image and remain competitive in their respective markets.

Inspection of raw materials

The quality of the raw materials used in the production of safety vests is of paramount importance. If the materials are not up to par, the entire vest may be compromised, putting the wearer at risk. As such, we cannot afford to take any chances when it comes to the materials we use.

Upon receiving the raw materials for your order at our warehouse, our dedicated Quality Control (QC) team will meticulously examine each component to ensure they meet your specifications. The QC team will thoroughly check various aspects, including size, color, function, weight, reflective performance, and fluorescent color, among others.

This comprehensive inspection process guarantees that the safety vests produced adhere to the highest quality standards and provide maximum protection to their wearers. By prioritizing the quality and integrity of our materials, we can confidently deliver safety vests that meet and exceed your expectations.

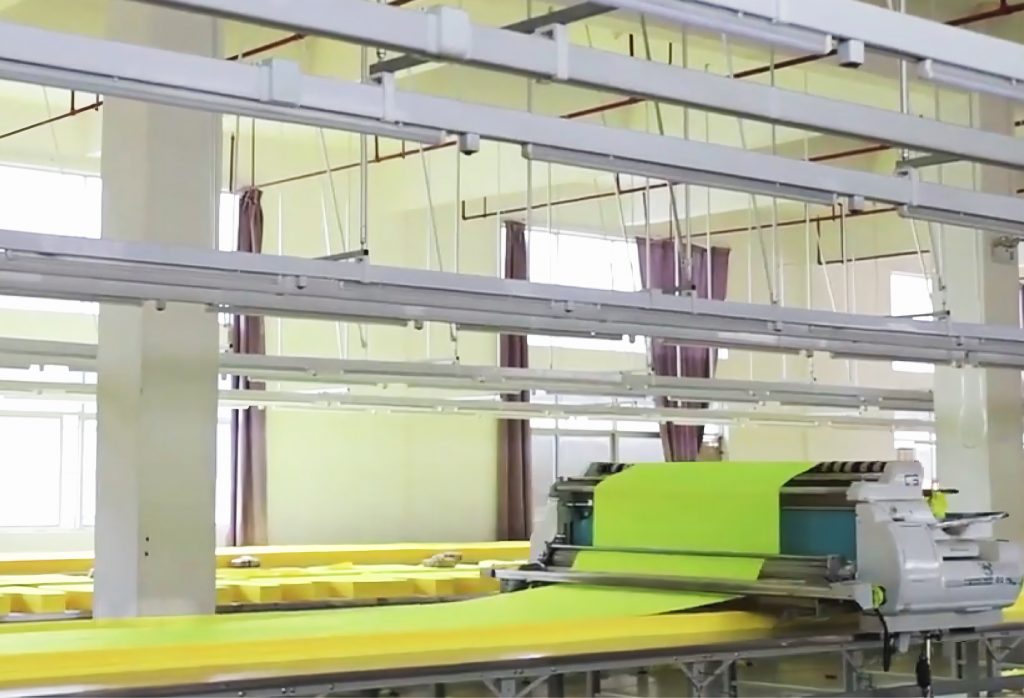

Fabric Cutting

Next, the fabric is cut into pieces using a digital cutting machine that follows the pattern precisely. Cutting is one of the most important steps in safety clothing making because this is where your ideal style comes out. With well-selected fabric in our hands, our makers will tailor your safety clothing according to your size & design needs. The automatic cutting machine ensures maximum precision in every size we make.

Safety Clothing Sewing

The pieces are then sent to the sewing department, where they are stitched together using industrial-grade sewing machines. Our skilled workers pay close attention to detail, ensuring that each seam is straight and secure.

Safety Clothing Online Inspection

We firmly believe that the key to guaranteeing high-quality safety vests lies in controlling every aspect of the sewing process. During production, our dedicated QC team closely monitors each stage, providing guidance to our workers and ensuring they adhere to the correct workmanship. By identifying and addressing any potential issues in real time, we ensure that every product meets the rigorous standards that our clients expect.

Trust Lino Safety to deliver exceptional quality and reliability through our meticulous online inspection process, which guarantees the finest safety vests for your business needs.

Final Inspection

At this stage, your safety clothing has been meticulously crafted, and we conduct a thorough inspection of each piece. Our experienced workers check for any flaws or imperfections in the fabric and workmanship, as well as ensure that zippers and Velcro fastenings function perfectly. We’ve got you covered, from design and sizing to every detail that matters to you.

Packaging & Delivery

At Lino Safety, we understand the importance of delivering our safety clothing in perfect condition. To achieve this, we carefully wrap each item and place it individually in the designated packaging. We offer a variety of packing options to suit both the specific safety clothing and your budget, ensuring your products arrive in the best possible condition.

How Can Safety Vests Benefit Your Business?

Safety vests are essential for anyone working in hazardous environments. They help to keep wearers visible and protect them from accidents and injuries.

At Lino Safety, we offer a wide range of safety vests that are suitable for a variety of industries, including cycling, running, construction, logistics, transportation, and emergency response. Our vests are designed with both safety and comfort in mind, and we use only the highest quality materials to ensure their durability and longevity.

Contact us today to learn more about how we can help you to boost your business.