When you have selected a style and requested a quotation from a supplier, they will often provide you with a sample for reference. How can you determine if the safety vest sample meets your requirements? In this article, I will explain step-by-step how to evaluate a sample based on product material, style, size, try-on, details, and workmanship, analyzing samples suitable for two different situations.

Shape

To check the shape of a safety vest sample, you should compare it to your design drawing and confirm that it matches your specifications. Here are the steps you can follow:

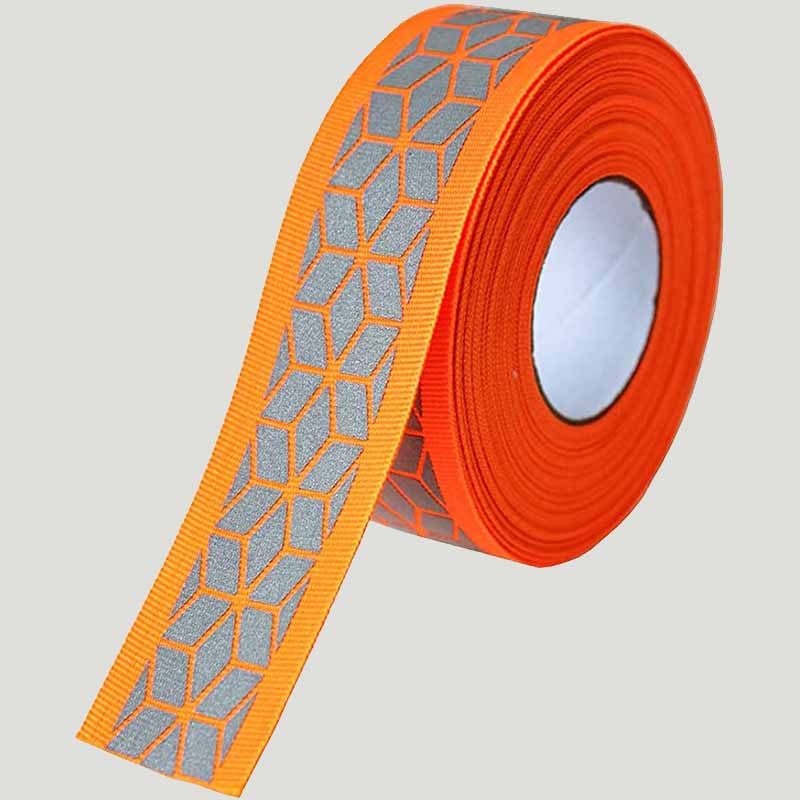

- Look at the sample from different angles and compare it to your design drawing. Check that all the design elements are present, including reflective strip placement, pocket placement, number of air holes, etc.

- Pay attention to the inside of the vest and check for missing pockets, piping, or other design elements.

- Ensure that all the parts are in the correct position and number and that nothing is missing.

- Take note of any differences between the sample and your design drawing.

If you find that the sample does not match your design drawing or that there are missing parts, you may need to request changes or adjustments to the sample before mass production. It’s important to communicate any necessary changes with the supplier to ensure that the final product meets your requirements.

Material

If you specified specific materials from the beginning, check if the fabric information is consistent. Specifying surface accessories is the fastest way, which is based on your mature experience. If you have specific requirements for the fabric, but not the specified material, usually the supplier will find suitable fabrics for you in the market according to your needs. At this time, evaluate whether the material meets your requirements, the feel of the fabric, and its functional characteristics. For example, you want a waterproof material, but the supplier has not treated the fabric with a film, and the zipper is also an ordinary zipper. This cannot meet your requirements.

At Lino Safety, we not only provide you with suitable fabrics for sample making but also offer multiple alternatives to choose from with the same functionality.

Size

To check the size of a safety vest sample, you should measure each part of the vest according to your size chart. Here are the steps you can follow:

- Lay the sample flat on a table or other flat surface.

- Use a tape measure to measure each part of the vest, such as the collar circumference, collar height, collar depth, shoulder width, sleeve length, cuff size, and pocket opening size.

- Compare the measurements to your size chart to determine if the sample matches your specifications.

- Take note of any differences between the sample measurements and your size chart.

It’s important to keep in mind that there may be slight variations between the standard size of the clothing and the size of the actual sample. However, as long as the differences are within an acceptable range, they should not affect the overall fit of the vest.

If you find that the sample size does not match your specifications, you may need to make adjustments before mass production. It’s recommended to communicate any necessary changes with the supplier to ensure that the final product meets your requirements.

Try-On

Trying on a sample is an important step in evaluating a safety vest sample because it allows you to assess the fit and comfort of the vest. Even if the size measurements match your size chart, the sample may not fit your body shape perfectly. By trying on the sample, you can check if the vest is too loose or too tight in certain areas, if the armholes or collar are too tight, or if the length is appropriate. You can also assess the comfort level of the vest, including the feel of the fabric, the weight, and the flexibility of the material.

If the sample does not fit well or is uncomfortable, it may not be suitable for practical use, and adjustments may need to be made before mass production. Therefore, trying on the sample is an essential step in ensuring that the final product meets your requirements and is comfortable to wear.

Detail

If you are satisfied with the above three steps, then the sample is 70% successful. Suppliers with better control usually have excellent details and workmanship.

Confirm that the product is intact and undamaged from the outside to the inside, such as whether the fabric has dirt marks or damage. Check for printed logos or patterns, whether they are correct, whether the size and position are correct, and whether there are traces of uneven dyeing or pattern peeling off. Finally, check the accessories, such as whether the zipper is smooth, whether the buckle is firm and can be closed under normal conditions, and whether the Velcro is sewn into the same condition on both sides.

Details determine success or failure, so excellent products often handle details well. If the details of all aspects of your product are good, it means that the supplier’s comprehensive strength is strong.

Workmanship

做工可以很好的体现产品的质量。优秀的产品做工应该是线头干净、线迹均匀、不漏线。衣服的反面显示了衣服的真相。考虑堆焊是否光滑,接缝处是否光滑,是否有很多未处理的螺纹。

Our safety vests are in the clothing category, so they have certain requirements for craftsmanship. The sewing of many parts requires workers to have rich production experience and corresponding equipment support. Therefore, the product’s workmanship directly reflects the manufacturer’s technical level.

Our Sample Service

At Lino Safety, we ensure that every step of the sample-making process is strictly controlled, and we maintain high quality regardless of price. You can preview our catalog or website products and request samples for reference.

If you have a confirmed drawing and size chart, we will create a pattern according to your requirements. Ideally, you already have confirmed fabrics and accessories. If you are still struggling to find suitable surface accessories, we will provide you with appropriate solutions.

We carefully inspect each sample before sending it out to ensure that we provide you with the most suitable samples with our serious attitude from beginning to end. If you have any other views or questions, please feel free to contact us. We are always happy to serve you.